Before extracting the metal from an ore, it is necessary to remove the impurities present in it. By removing these impurities we get a concentrated ore which contains a high percentage of metal in it. The process of removal of gangue particles from ore to increase the percentage of metal in ore is called enrichment of ore. The processes used for removing the impurities from ores depend on the difference between physical or chemical properties of the ore and of the impurities.

Methods of enrichment of ore:

Now, we shall discuss the different processes which are used for the enrichment of different types of ores.

1. Hydraulic Washing

This method is used for the enrichment of those ores which are heavier than gangue particles present in them. In this method, a stream of water is passed through crushed and finely powdered ore. The Lighter gangue particles are washed away with water while the heavier ore particles are left behind. Oxide ores of tin and lead are concentrated by this method.

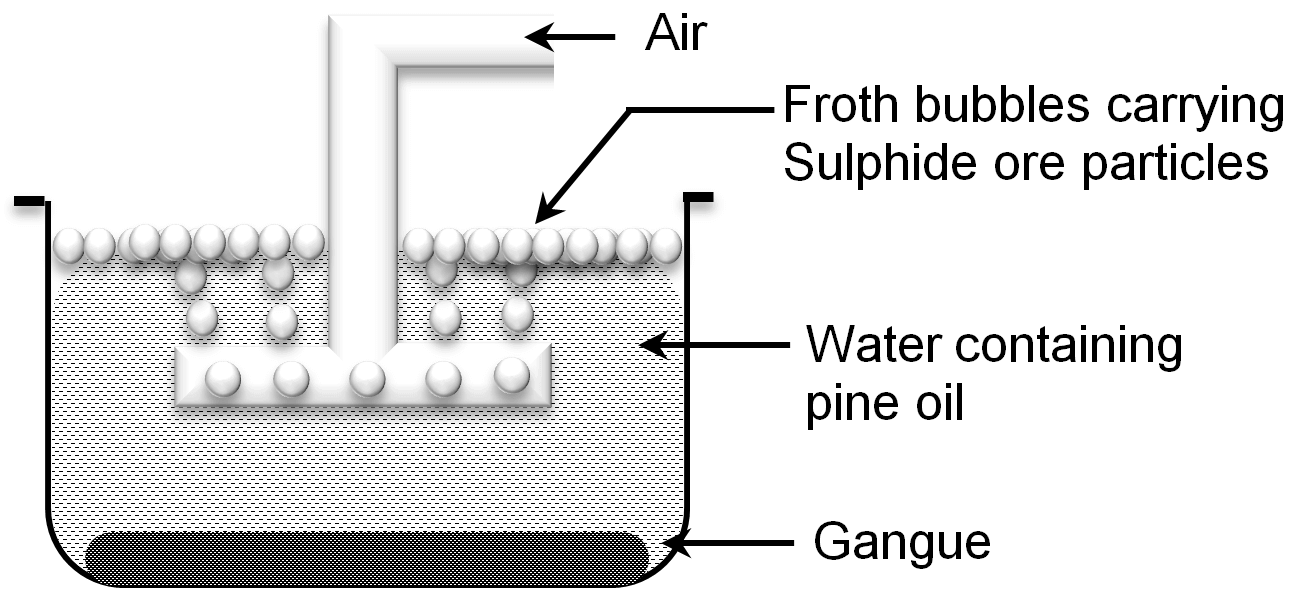

2. Froth Floatation Process

This method is used for concentration of sulphide ores of copper, lead and zinc. In this method, powdered ore is put in a tank full of water. And then, some Pine oil is added to it. In the tank, the particles of sulphide ore are wetted by pine oil whereas the gangue particles are wetted by water. Then the air is passed through this mixture. This results in the agitation of water in the tank, which causes the sulphide ore particles to stick with the oil and rise to the surface in the form of froth. The gangue particles being heavier remain behind at the bottom of the water tank. The froth is separated and concentrated sulphide ore is obtained from it.

3. Magnetic Separation

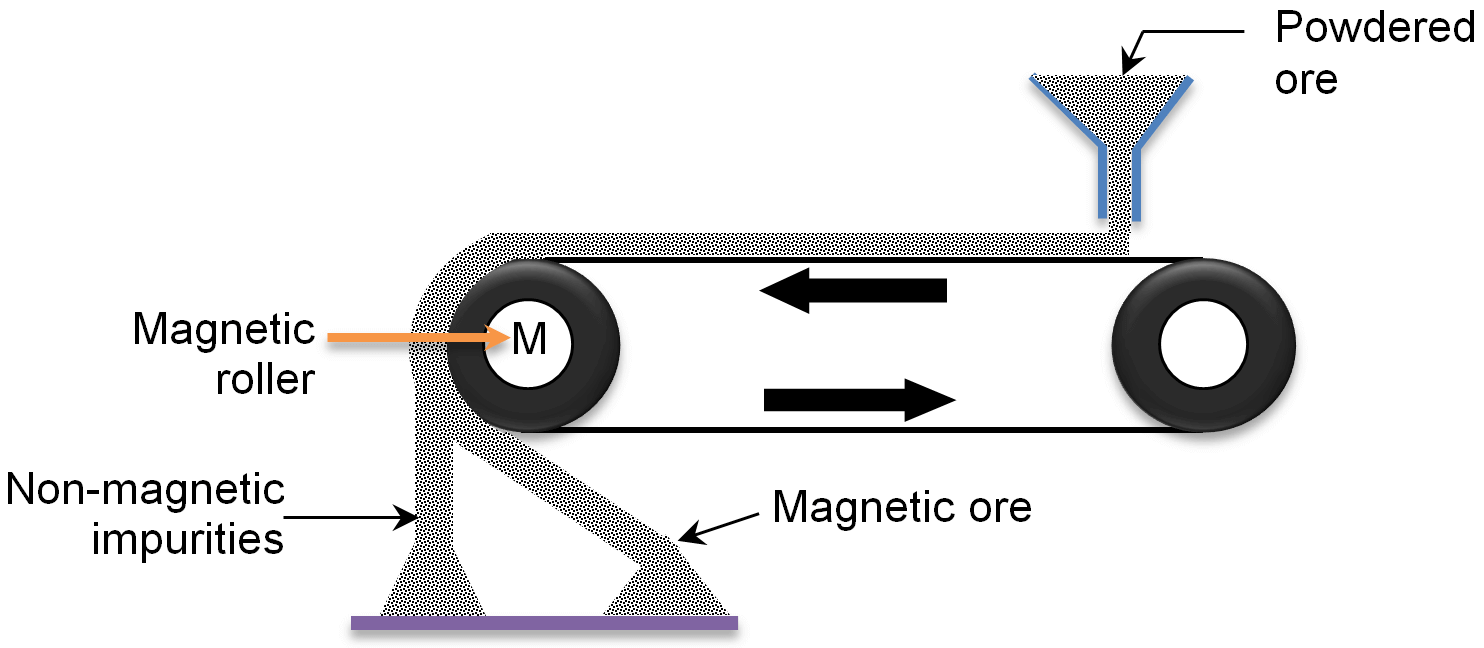

This method is used for the concentration of magnetic ores of iron (magnetite and chromite) and manganese (pyrolusite) by removing non-magnetic impurities present in them. This process involves the use of a magnetic separator.

A magnetic separator consists of a leather belt which moves over two rollers. Out of two rollers, one roller has a magnet in it. In this method, the finely powdered magnetic ore is dropped over the moving belt at one end. When the powdered ore falls down from the moving belt at the other end having a magnetic roller, the particles of ore are attracted by the magnet and form a separate heap from the non- magnetic impurities.

4. Chemical Separation

This method is based on the differences in some chemical properties of the gangue and the ore. For example, the impure ore of metal aluminium (bauxite or aluminium oxide) is concentrated by Baeyer’s process.

Baeyer’s Process

In Baeyer’s process, the finely powdered bauxite ore is treated with hot sodium hydroxide solution to form a water soluble compound called sodium aluminate.

Al2O3 + 2NaOH → 2NaAlO2 + H2O

(Bauxite + Sodium hydroxide → Sodium aluminate + Water)

The gangue present in bauxite does not react in sodium hydroxide sol, so the gangue can be separated by the process of filtration. After filtration, the filtrate containing a solution of sodium aluminate is acidified with HCl to form precipitates of aluminium hydroxide.

NaAlO2 + HCl + H2O → Al(OH)3 + NaCl

(Sodium aluminate + Hydrochloric acid + Water → Aluminium hydroxide + Sodium chloride)

The precipitates of aluminium hydroxide are then filtered, washed, dried and heated to get pure aluminium oxide.

2Al(OH)3 → Al2O3 + 3H2O

(Aluminium Hydroxide → Aluminium Oxide + Water)

It should be noted that pure aluminium oxide is also known as alumina.

Test your understanding and answer these questions:

- What do you understand by enrichment of ore?