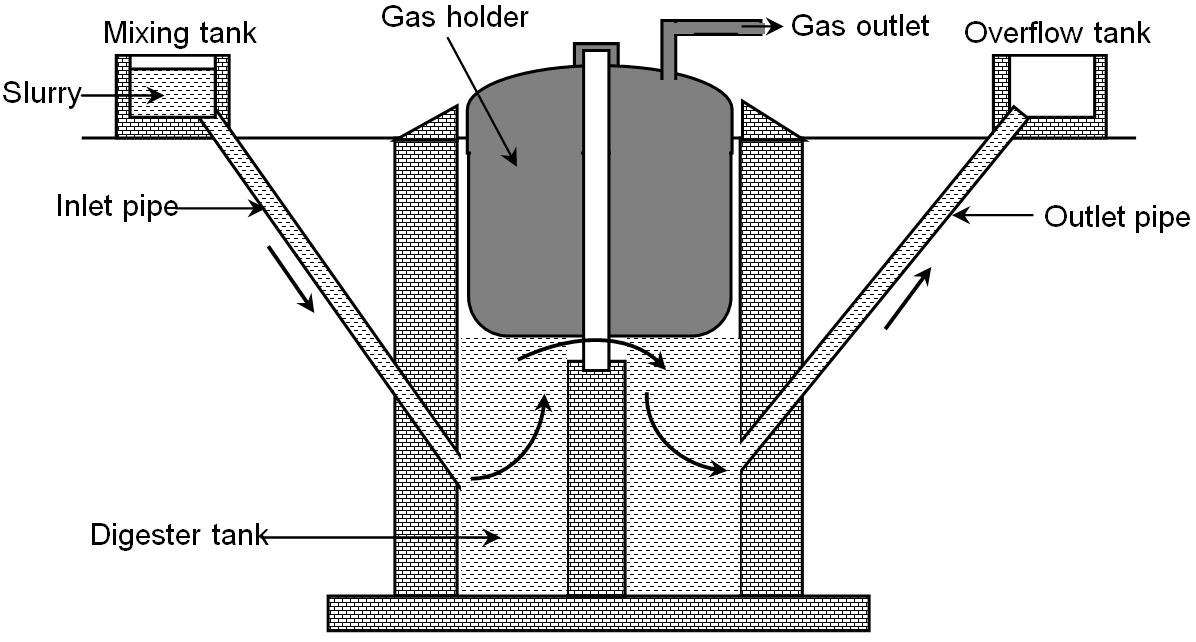

The floating gas holder type bio gas plant consists of a dome shaped gas holder made of steel for collecting bio gas. The dome shaped gas holder is not fixed but is moveable and floats over the slurry present in the digester tank. Due to this reason, this biogas plant is called floating gas holder type biogas plant.

Slurry is prepared by mixing water in cattle dung in equal proportion in mixing tank. The slurry is then injected into a digester tank with the help of inlet pipe. The digester tank is a closed underground tank made up of bricks. Inside the digester tank, the complex carbon compounds present in the cattle dung breaks into simpler substances by the action of anaerobic microorganisms in the presence of water. This anaerobic decomposition of complex carbon compounds present in cattle dung produces bio gas and gets completed in about 60 days. The bio gas so produced starts to collect in floating gas holder and is supplied to homes through pipes. And the spent slurry is replaced from time to time with fresh slurry to continue the production of bio gas.

Test Your Understanding and Answer These Questions:

- How floating gas holder type bio gas plant works?